-

Tel:+86 18948187408

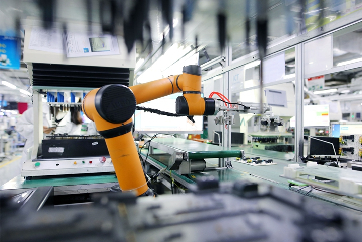

cross border logistics Five manufacturing sites in China were newly selected as Lighthouse factories by the World Economic Forum (WEF), bringing the total in China to 42, more than one-third of the global total, pointing to China's continuously rising manufacturing sector.

China's intelligent manufacturing is advancing steadily, with the upgraded manufacturing sector expected to play a larger role in stabilizing global industry and supply chains amid growing external challenges, experts said.

The factories are leading Chinese battery maker CATL's facility in Yibin, Southwest China's Sichuan Province, Chinese home appliance company Haier's factory in Qingdao, East China's Shandong Province, Midea's factory in Shunde, South China's Guangdong Province, Chinese high-end equipment manufacturer Sany Heavy Industry's factory in Changsha, Central China's Hunan Province and US computer hard disk drive manufacturer Western Digital's site in Shanghai, according to the WEF.

The Global Lighthouse network is a community of manufacturing sites that show leadership in the adoption and integration of cutting-edge technologies of the Fourth Industrial Revolution.

Compared with developed economies such as the US and Japan - with nine and two Lighthouse factories, respectively - China has 42 such sites, accounting for 36.8 percent of the global total. Most such factories in China are invested in by local Chinese companies.

The latest manufacturing site is the fifth of Midea to be designated as a Lighthouse factory. It's the world's largest dishwasher production base, manufacturing up to 6 million machines annually for export to 145 countries and regions, according to a press release sent to the Global Times on Wednesday.

According to the WEF, the factory has deployed artificial intelligence (AI), digital twin and other emerging technologies in the end-to-end value chain, achieving 24 percent lower unit production costs, 41 percent shorter lead times and 30 percent shorter research and development lead times.

The CATL plant further deployed in-depth AI, the Internet of Things and flexible automation on top of the CATL Ningde headquarters Lighthouse digital initiatives, and it has achieved 17 percent faster line speed, 14 percent reduced yield loss and zero carbon emissions, read a statement by the WEF.

"The admission of more Chinese manufacturing sites to the Global Lighthouse Network underscores the steady progress of the Chinese intelligent manufacturing sector, which takes the lead in terms of scale," Liang Zhenpeng, a senior industry analyst, told the Global Times on Wednesday.

However, there is still room for improvement to catch up with some developed economies in areas such as new types of sensors, as well as core technologies in software and robots, Liang said, noting that it's a matter of time for China to make breakthroughs with a new system for mobilizing these resources nationwide.

To promote the development of intelligent manufacturing, the Ministry of Industry and Information Technology announced a plan in September to create a series of scenarios with high technical level and application value, and make breakthroughs in core technologies, equipment and software, among other areas.

The authorities will select scenarios that can be generalized at factories and workshops, while constructing demonstration plants in areas including raw materials, equipment production and consumer goods.

Global Times